Cell-free protein synthesis (CFPS) technology has experienced an impressive growth in recent years in what concerns applications and the types of molecules that it can advantageously produce. One example is the synthesis of enzymes.

Advantages of CFPS for enzyme production

Production of various enzymes has shown to be favourably performed by cell-free systems, due to different reasons. For enzymes that are cytotoxic, CFPS provides a means to overcome the difficulties faced with cell-based production. A well-known example is onconase, an enzyme that is a promising anti-cancer drug, which has been efficiently produced in a cell-free system in an active form, with 95% solubility and at a yield of 1,86 mg/ml [1], higher than the yield achieved with in vivo systems [2]. Other enzymes are membrane proteins, and cell-free systems enable their effective production as CFPS is flexible in supplementing membrane mimics (such as liposomes and nanodiscs), surpassing the obstacles of cell-based synthesis. For example, protein glycosylation B (PglB), an oligosaccharyltransferase from Campylobacter jejuni, was synthesized in an active form using an Escherichia coli cell-free system with lipid nanodiscs, at yields of up to 420 μg/ml [3].

From small to bigger proteins !

The outer membrane proteins of Gram-negative bacteria are useful targets for the development of vaccines since most of them expose epitopes of the bacterial surface that can be recognized by the host immune system. In P. aeruginosa, From small polypeptides, cell-free systems have improved their performance and are now able to synthesize functional and large protein complexes. This is achieved because cell-free reactions allow the simultaneous translation of various mRNAs, thus permitting the synthesis of multi-unit structures. Furthermore, the open nature of cell-free systems enables to adjust and optimize the reaction and assembly conditions. Additionally, CFPS systems can couple encoded protein expression to assembly of protein complexes, which may help to clarify the role of genetic regulation on assembly mechanisms [4]. Diverse studies have demonstrated the favourable synthesis of enzymes with complex structures by cell-free systems. For example, a cell-free system was developed to express and assemble a bacterial F1F0-ATP synthase originating from the Caldalkalibacillus thermarum strain TA2.A1, using E. coli extracts [5]. This synthase is a large mixed membrane protein complex that consists of two major structural domains: the F1 complex is an assembly of nine soluble proteins and the F0 complex contains the membrane-embedded proteins. The 542-kDa membrane protein complex comprising 25 proteins (9 soluble and 16 membrane-embedded proteins) was produced, presenting its specific activity, as well as structure and subunit organization identical to the in vivo expressed ATP synthase.

Enzyme structure

Complex polymerases also produced in CFPS

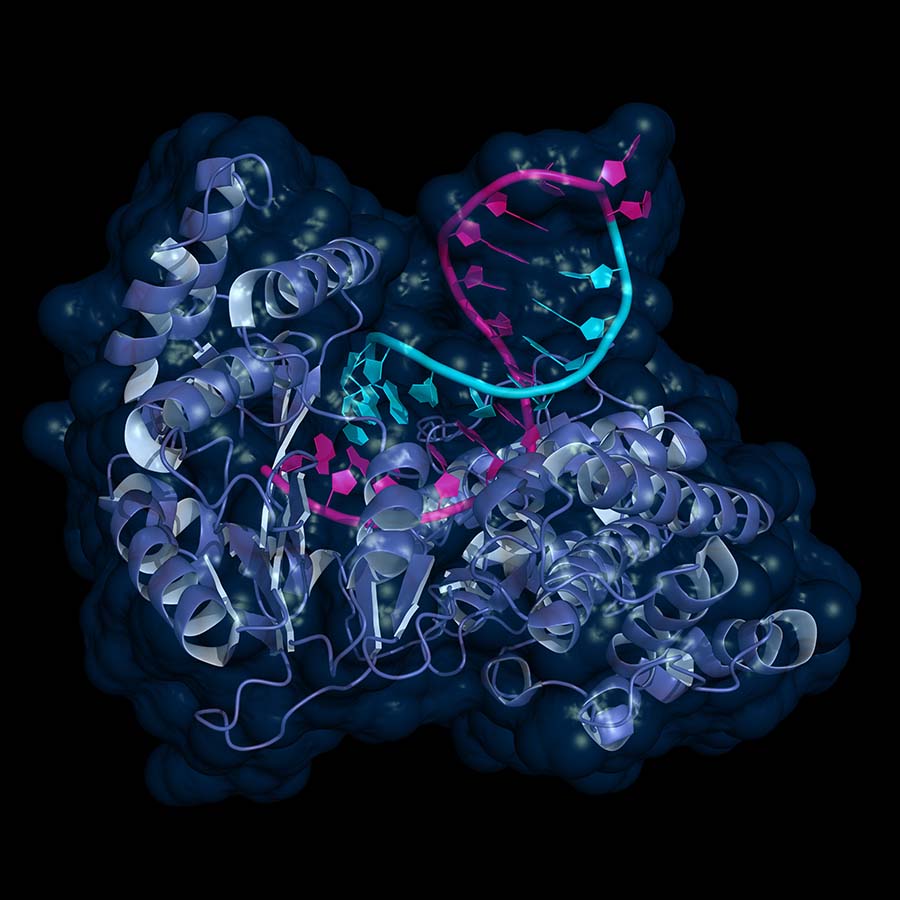

CFPS has also been used to express chromosomal DNA replication proteins, namely DNA polymerase III, a hetero protein complex composed of 17 subunits and 9 different proteins [6]. The authors used a PURE system and were able to implement a complete sequential transcription-translation-replication process, in which DNA replication proteins could be synthesized. Furthermore, the synthesis of a five-subunit E. coli RNA polymerase was performed using a cell-free system that allowed co-expression of genes encoding E. coli RNA polymerase subunits and sigma factors, enabling to couple the synthesis and assembly of a functional RNA polymerase holoenzyme with the expression of a reporter gene [7]. With this strategy, a sigma-factor-dependent promoter-specific transcription initiation was demonstrated, and protein synthesis, complex formation and enzyme catalysis could be performed in the same in vitro reaction mixture. Hence, if you need to produce a particular enzyme, keep in mind that cell-free expression technology can help you. The described examples show the success that CFPS has been achieving in the production of diverse enzymes.

Synthelis

Since 2011 Synthelis has developed a proprietary cell-free expression system combined with a strong know-how to define optimized CFPS conditions to produce almost any protein of interest. Among the different proteins successfully produced by Synthelis’ team, several ones are enzymes. Also, if you have any project requiring the quick and efficient development of enzymes, please contact us…

Sources

[1] Salehi A.S.M., Smith M.T., Bennett A.M., Williams J.B., Pitt W.G., Bundy B.C. 2016. Cell-free protein synthesis of a cytotoxic cancer therapeutic: onconase production and a just-add-water cell-free system. Biotechnol. J. 11:274-281. http://dx.doi.org/10.1002/biot.201500237

[2] Notomista E., Cafaro V., Fusiello R., Bracale A., D’Alessio G., Di Donato A. 1999. Effective expression and purification of recombinant onconase, an antitumor protein. FEBS Lett. 463:211-215. https://doi.org/10.1016/S0014-5793(99)01623-3

[3] Schoborg J.A., Hershewe J.M., Stark J.C., Kightlinger W., Kath J.E., Jaroentomeechai T., Natarajan A., DeLisa M.P., Jewett M.C. 2018. A cell-free platform for rapid synthesis and testing of active oligosaccharyltransferases. Biotechnol. Bioeng. 115:739-750. https://doi.org/10.1002/bit.26502

[4] Perez J.G., Stark J.C., Jewett M.C. 2016. Cell-free synthetic biology: engineering beyond the cell. Cold Spring Harb. Perspect. Biol. 8:a023853. https://doi.org/10.1101/cshperspect.a023853

[5] Matthies D., Haberstock S., Joos F., Dötsch V., Vonck J., Bernhard F., Meier T. 2011. Cell-free expression and assembly of ATP synthase. J. Mol. Biol. 413:593-603. https://doi.org/10.1016/j.jmb.2011.08.055

[6] Fujiwara K., Katayama T., Nomura S.M. 2013. Cooperative working of bacterial chromosome replication proteins generated by a reconstituted protein expression system. Nucleic Acids Res. 41:7176-7183. https://doi.org/10.1093/nar/gkt489

[7] Asahara H., Chong S. 2010. In vitro genetic reconstruction of bacterial transcription initiation by coupled synthesis and detection of RNA polymerase holoenzyme. Nucleic Acids Res. 38:e141. https://doi.org/10.1093/nar/gkq377