Cell-Free

Technologies.

We are protein biodesigners

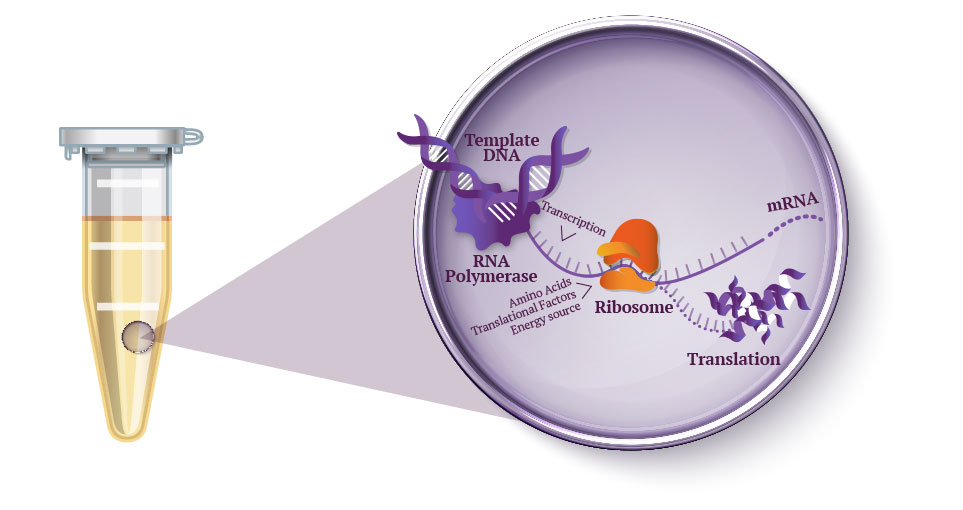

Protein production technologies in a “cell-free” system consist of using cell extracts (or lysates) containing all the natural machinery of transcription and translation, to produce, in-vitro (in a tube, a flask, a bioreactor etc), one or several biomolecules of interest for the pharmaceutical industry, the diagnostic sector, the synthetic biology, the food industry and more generally for the bioeconomy.

With this technology, the production system is not based on the multiplication of genetically modified cells, but on the in-vitro use of components extracted from the cytoplasm of the cells, thus elements naturally present in any cell.

In this way, the machinery is dedicated to one, or just a few, proteins of interest, which allows, in most cases, a drastic increase in production yields – a primary advantage of the technology

General principle of the Cell-Free technology

STEP 1 – PREPARATION OF THE REACTION MIXTURE

STEP 2 – PROTEIN EXPRESSION

The main advantages of cell-free systems

Production of difficult proteins: membrane proteins, cytotoxic proteins, unstable proteins, non-natural proteins…

A strong improvement in expression yields.

Obtaining correctly conformed and functional proteins, by adding chaperones, cofactors etc. made possible by the open nature of the system.

A shortening of the production time: a few hours versus week(s) for cellular systems.

Site-specific insertion of non-canonical amino acids.

Easier and more homogeneous labelling of proteins.

Reduction of inter-batch variability.

Great flexibility of use: from microplate to hundreds of litres.

Diagram of a Cell-Free systems

The cell extract is the basis of the system. It is supplemented by compounds necessary for the expression of a gene into a protein: DNA matrix, nucleotides in the form of Nucleotide Triphosphates (NTPs), carbon energy source, tRNA, 20 amino acids etc. As it is an open system, any additive and cofactor helping the expression and the structuring of the protein can be added.

The different cell-free systems

Systems based on prokaryotic lysates

These systems are the most commonly used because they enable the best productivity in terms of expression (several mg/mL for some proteins) at the lowest cost. They are also easier to implement. Their main limitation is that they do not perform post-translational modifications (glycosylation, phosphorylation etc.) except for the establishment of disulfide bridges. However, these modifications can be achieved through the incorporation of amino acids carrying these modifications or in post-production by chemical couplings.

Systems using eukaryotic lysates

A growing number of cell-free systems based on eukaryotic lysates have been developed in recent years to produce complex proteins. They have the advantage of performing post-translational modifications often required for the activity of proteins of pharmaceutical interest. The diversity of eukaryotic systems developed for cell-free expression means that the best and most suitable system can be identified resulting in the high-quality production of the protein of interest. The disadvantage of such systems remains their expression yields, which are lower than cell-based systems and prokaryotic cell-free systems for many proteins.

The reconstituted cell-free system

This system is marketed under the term “PURE system”. Its base is not made up of a cell extract, but of the assembly of the 36 proteins necessary for the transcription steps of a gene into mRNA and then of the translation of this mRNA into protein. This system has the advantage of obtaining a relatively pure product before any purification stage. It also allows the precise ratio modulation of the different components of the production machinery and a better understanding of their respective influence. This system can be compared to the “precision clockwork” of cell-free technologies. It is used for small-scale expression because it remains expensive and often offers low yields.

Cell-free systems can be developed from almost any cell type.

Fields of application

Field

Biomedicines

Field

Synthetic biology

Field

Bioproduction

Field

Structural biology

Field

Bioeconomy

Field

Point-of-care bioproduction

10 myths

about Cell-Free

systems

that you probably always believed