Cell-Free

Protein

Synthesis.

high-throughput platform:

faster and smarter!

Step 1/

Feasibility study

Étape 2/

Sample production

Step 3/

Protein characterization

Étape 4/

Production

The following options for our cell-free expression offering are available:

– from our proprietary system based on E.coli lysate

For over 15 years we have developed and optimized an expression system based on an E. coli lysate offering high expression yields and delivering high-quality, well-conformed and active proteins. This quality is obtained by researching and defining the optimal expression conditions for the protein of interest.

– From almost all existing eukaryotic systems: Rabbit Reticulocyte Lysate (RLL), Insect, CHO, Human…

– From a custom-developed lysate (cell type desired by the customer)

Because we have mastered the expression of complex proteins and cell-free technology, we are able to achieve high yields for a wide range of functional proteins, including membrane proteins and cytotoxic proteins.

Overcomethe limits of cell-based systems!

The benefits of the Synthelis Cell-Free approach

Preserved functionality with full size proteins.

Quantity: from 10 µg to 100 mg

Speed: feasibility studies are performed in 2-3 months and production of previously expressed proteins requires 1-2 weeks per mg of protein*.

*Example: 1 week for 1 mg of CXCR4 or Bak protein. Lead times may vary depending on the results of the feasibility study or the expression level of each protein.

High success expression rate: over 90% of the proteins were successfully expressed.

Functionality: 80% of the proteins tested are functional.

Step 1/

Feasibility study

Discussion of your project and your expectations

As soon as you have informed us of your request, we will set up an initial telephone or video meeting to discuss your project, in order to fully understand your needs and objectives. A confidentiality agreement can be put in place, if necessary at this stage.

Preliminary study and quotation

Literature review and sequence analysis

Based on the information given by the client, we will search the literature and/or analyze the articles provided to identify the necessary conditions and the system that will work best to express your protein of interest. We will then gather all the conditions that have a positive impact on the expression of the protein as well as assess any potential difficulties that we may encounter.

Using protein databases and our sequence analysis tools, we will establish, based on this preliminary study, a work plan, and an estimate of costs to quickly and efficiently evaluate our ability to produce your protein of interest.

Optional: in-silico protein engineering

Synthelis has developed extensive partnerships with artificial intelligence companies which have developed proprietary solutions to predict in-silico the characteristics of the proteins. By leveraging these relationships, we can generate very quickly, and effectively, a library of mutants that will have the specific or optimized property you are looking for in your product or reagent: increased stability, improved activity, stronger affinity, better specificity etc.

Design and construction of the expression vector

The design of the DNA construct is also a critical stage in the process; one where the experience of a specialist plays a key role and increases the chances of success for a protein production project.

The right choice of expression tag (6xHis, Avi, Strep etc.), its positioning in relation to the gene, the size of the sequence between the tag and the coding region, the selection of the promoter etc, are all factors influencing the level of expression, the purification and the correct folding of the protein.

With more than 15 years of experience in protein production and a network of partners specialized in molecular biology, we can identify the DNA construct(s) that will enable the optimal expression and purification of your protein of interest.

Screening of expression conditions

Once we have a ready-to-use DNA construct, we will test the different key parameters for each expression system used:

– Salt concentration, cell extract type, T°C etc. for the cell-free protein synthesis system (CFPS).

– T°C, medium, clones etc, for E. coli based systems

The combination of parameters giving the best expression level and a whole protein, soluble if necessary, will be selected at this stage by Western Blot analysis.

– Estimation of the expression yield.

When the best expression conditions are defined, a small-scale production is carried out to allow the development of the purification protocol and to estimate the production yield of the protein.

Final formulation

The choice of the final buffer is a critical stage in the process and one where our experience can help guide you to the most suitable solution for your application.

We offer all the main chromatography techniques, which, when combined with our know-how, will define the correct conditions to purify your protein of interest. Based on expected purity levels we can implement:

Different affinity chromatography techniques (IMAC, protein A etc.)

These techniques will use the protein affinity itself (antibody, protease for example), or its associated label, to achieve highly selective protein purification, even in a complex mixture. These techniques make it possible to quickly obtain a protein with high levels of purity.

Ion exchange chromatography (IEC)

This is a predictive method using the isoelectric point (pI) of the protein to achieve its purification. Although it has limited selectivity, it is a highly robust method and can be efficiently used as a first line method, especially with tagless proteins.

Hydrophobic Interaction Chromatography (HIC)

The method uses the hydrophobic domains of the protein to retain it on a resin. This technique, although not particularly predictive, can be used to complement other methods.

Size exclusion chromatography (SEC)

A technique which is based on the apparent diameter of the protein (depending on its molecular weight and its oligomeric state). This technique is a highly efficient means of improving protein purity and of modifying the final buffer.

We are also able to offer complementary methods depending on the physicochemical properties of proteins.

In the case of membrane proteins in proteoliposome format, the purification is performed by sedimentation on a sucrose gradient. This allows the purification of the liposome fraction which has integrated the membrane protein of interest, but does not allow the elimination of all protein impurities coming from the bacterial lysate of our cell-free system.

In order to eliminate the possible interference of these impurities in your application, we offer “negative control” proteoliposomes containing the same impurities, but without your protein of interest.

Step 2/

Sample production

When the best expression conditions are defined, a small-scale production is carried out to allow the development of the purification protocol and to estimate the production yield of the protein. The resulting purified product is then either shipped to the customer for testing or used for quality control testing at Synthelis.

Step 3/

Protein Characterization

To guarantee the quality of the proteins we have synthesized for you or that you have produced, we offer our qualitative analysis services. These analyses allow us to determine purity levels for proteins of interest, to validate their identity and to study the homogeneity of the solutions obtained.

Certain analyses such as SDS-Page control and Western-blot analysis are included in our protein production offerings to ensure the purity and identity of the product obtained.

Depending on your needs, we can complete this offering with different methods allowing a more in-depth study. We can check the identity and integrity of the protein using mass spectrometry, analyze the oligomerization state by SEC, SEC-MALS or DLS and study the stability of the protein by TSA. We can also check for the presence of endotoxins and verify the sterility of the product.

Methods - Protein/Sample Information

SDS-PAGE (reducing and non-reducing conditions) - Purity

Western blotting - Identity and integrity

Mass Spectrometry - Exact molecular weight and sequence

Size Exclusion Chromatographie (SEC) - Oligomeric status and purity

Thermal Shift Assay (TSA) - Protein stability

LAL - Endotoxin level determination

Sterility testing - Absence of viable microorganisms

RP- & SE-HPLC - Identity and purity

nanoDSF - Stability and folding

In order to better characterize the proteins produced in our systems, be they cell-free or cellular, we offer different quantification methods to meet your specific needs.

We include, as standard, a UV assay to determine the protein concentration obtained in solution, or for proteins produced in proteoliposomes, a quantification on SDS-PAGE gel.

Depending on your projects, we can also perform other quantifications such as Bradford or Pierce type colorimetric assays and amino acid assays.

Methods - Protein/Sample Information

SDS-PAGE - Specific quantities

UV assay - Total quantity of protein

Colorimetric assay - Total quantity of protein

Amino acid assay - Total quantity

Interactions between proteins lie at the heart of most cellular processes and are essential for a large number of functions in the living world. These interactions are notably involved in signal transduction, protein complex formation, protein transport, activation or inhibition of metabolic pathways etc.

Synthelis can offer interaction studies of your protein of interest with its ligand. There are many methods to investigate protein-protein interactions with each method having its own advantages and disadvantages. We offer a wide variety of techniques: SPR, BLI, ITC, FRET or MST so that clients can choose the most suitable technique for their project.

We have access to the following instruments for these analyses:

Monolith NT.115 (MST)

Octet® RED96e (BLI)

Biacore T200 (SPR)

PEAQ-ITC (very sensitive and requires small sample volumes)

Methods - Protein/Sample Information

ELISA

Microscale thermophoresis (MST) - Specificity and affinity

BLI - Specificity and affinity

SPR - Specificity, Kd, Kon, Koff

PEAQ-ITC - SBinding stoichiometry (n), affinity constant (KD), and enthalpy (ΔH) and entropy (ΔS) changes

We can verify the activity of your proteins through enzymatic activity assays, electrophysiological assays on Orbit Mini (Nanion) and we can also, depending on your needs, develop and perform custom activity assays.

Methods - Protein/sample information

Patch-clamp - Channel activity

Enzyme activity - Functionality

Custom assays - FFunctionality

Radio ligand binding - Specific activity

Finally, we can offer you several structural analyses, ranging from the evaluation of secondary structures by Circular Dichroism (CD) or Fourier Transform Infrared Spectroscopy (FTIR), to the resolution of three-dimensional structure by cryo-electron microscopy (Cryo-EM), Nuclear Magnetic Resonance (NMR) spectroscopy or by crystallography and X-ray diffraction.

For these analyses, we have access to the following instruments:

Transmission electron microscopes:

FEI Tecnai F20 200kV FEG

Thermo Scientific GLACIOS 200kV FEG

Spectrometers:

950 MHz Bruker Avance III HD Liquid/Solid

850 MHz Bruker Avance III HD Liquid

600 MH Bruker Avance III HD Liquid/Solid

Crystallography and X-ray diffraction:

TTP-Labtech nanovolume crystallisation robot and visualisation robot

Access to the ESRF synchrotron

Methods - Protein/sample information

Circular Dichroism - % secondary structures

Fourier Transform Infrared Spectroscopy (FT-IR) - % secondary structures

Atomic Force Microscopy (AFM) - Protein orientation and transmembrane domain validation

Cryo-EM - Three-dimensional structure

X-ray diffraction - Three-dimensional structure

NMR

Step 4/

Production

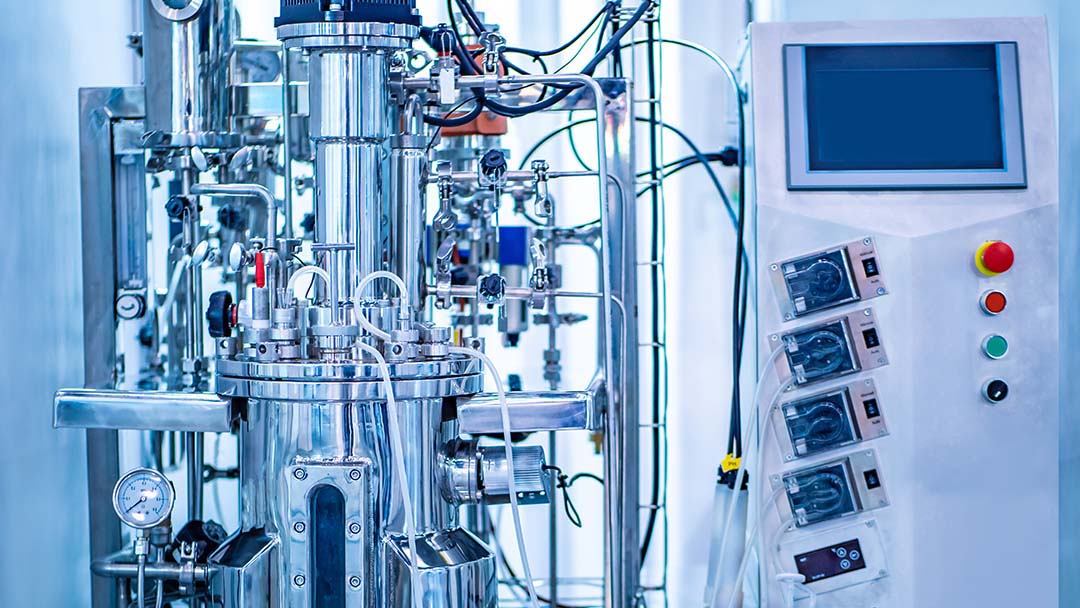

From design to purification, we optimize every step to maximize the expression and quality of your protein. Depending on your needs, cell-free production can be adapted to different scales. For screening or optimization phases, we produce small volumes (from a few microliters to a few milliliters), enabling rapid, parallel expression of several variants of a protein. This approach is ideal for testing different expression conditions, optimizing a protein’s structure or selecting the best functional version before scaling up.

When larger quantities are required, production can be rapidly scaled up to several milliliters or liters, using the optimized conditions defined during the development phase. Thanks to our mastery of cell-free systems, we can ensure efficient expression with high yields, suitable for applications ranging from basic research to protein production for preclinical testing or industrial bioprocessing.

The flexibility of cell-free also means that production can be rapidly adjusted to meet requirements, without the delays and constraints associated with cell culture. Whether you need to produce a few micrograms of rare proteins or several milligrams for functional or structural studies, our expertise guarantees optimized, reproducible production.

Case studies

Research project designed for Sanofi Pasteur (pdf)

Solubilisation of a strongly aggregated vaccine antigen

We look

forward to

your questions

Even

a protein

needs

to express

its potential.

Cell-Free Systems Applications